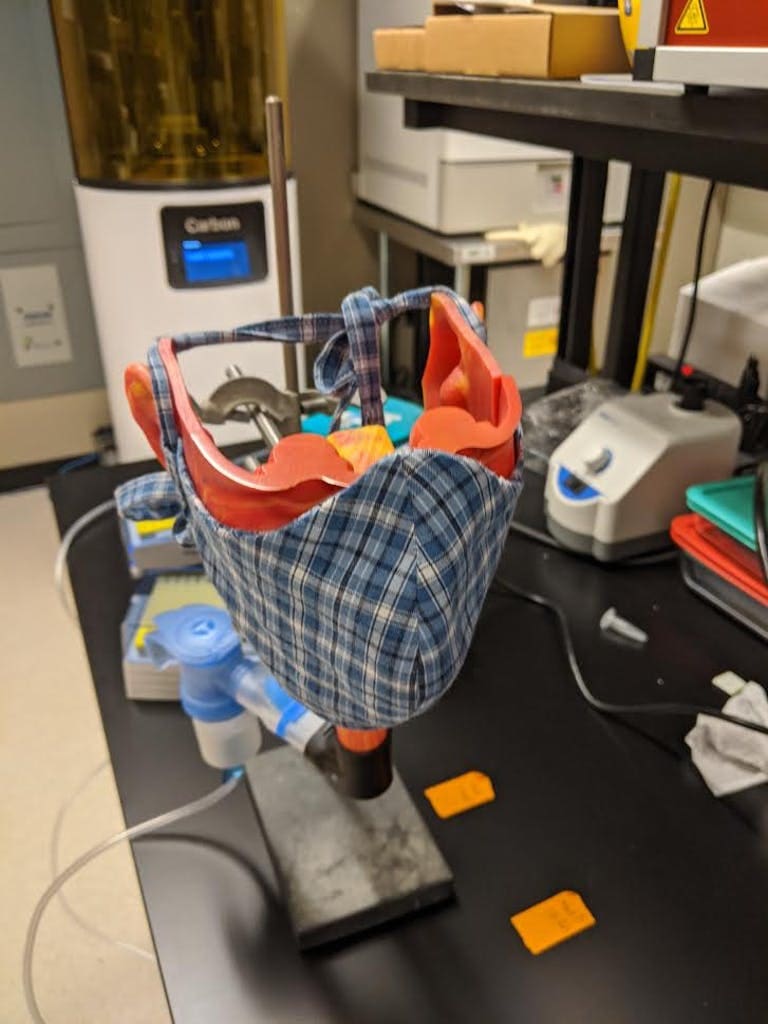

UD engineers 3D printed a face, nose, mouth and esophagus to tests face masks.

University of Delaware researches testing masks helped them find the best one on the market, as well as confirm how masks should be worn and what kind of material works best.

The team used a 3D printer and a nebulizer — a machine that turns liquid into a mist — to run their tests.

It found, to no one’s surprise, that the N95 masts with a tight fit is the most protective mask a person can wear. They are also among the most difficult.

Cathy Froman, the engineering professor leading the research group, said a cotton fabric mask with multiple layers is the next best option.

A key to maximizing the protection for yourself and others around you is for the mask to fit tightly.

Error, group does not exist! Check your syntax! (ID: 11)

“If your mask is fogging up your glasses,” Froman said, “the mask isn’t fitting properly.”

The idea for their research started when the pandemic closed UD March 23.

Cathy Fromen, Emily Kolewe, Zach Stillman and Ian Woodward were brainstorming research ideas via Zoom classes, with an eye to seeing how they could help. The project was planned online.

This 3D printed face was used to test mask at UD.

By the time UD’s facilities reopened, the ream was ready to go.

“One person was in the lab conducting the experiment and the rest of us had been on Zoom providing feedback,” Froman said. “We were forced to get creative.”

The research team 3D printed a face, nose, mouth and esophagus that was then paired with a nebulizer to simulate the aerosols that are expelled into the air while breathing.

What the research team found was that when wearing a mask, aerosols get trapped in the mask and clump together.

The ones that inevitably escape through the mask are too large to remain suspended through the air. They fall to the ground, lessening the chance they will transfer the virus to someone else through the air.

“If aerosol has another way to get out, it will go that way,” Froman said. “That’s why it’s important have a tightly sealed mask.”

UD engineers 3D printed a face, nose, mouth and esophagus to tests face masks.

Froman said the best way to make sure a mask protects both you and others is to ensure the mask fits tightly around your cheeks, under your chin and pinches around your nose.

Error, group does not exist! Check your syntax! (ID: 11)

Another way to improve the effectiveness of masks is to place a coffee filter between layers of the mask.

“The goal is to have good filtration with a good seal,” Froman said.

Froman said their research applies specifically to the 3D printed face that they used, and that one of the biggest findings in their research is that no one mask is best for everyone.

The researchers hope that the processes that they created to test the effectiveness of masks can be used in the future design and manufacturing of masks.

Different styles and shapes of faces could be 3D printed and the same tests could be ran on those models to determine which kind of mask would best fit different kinds of faces.

Share this Post